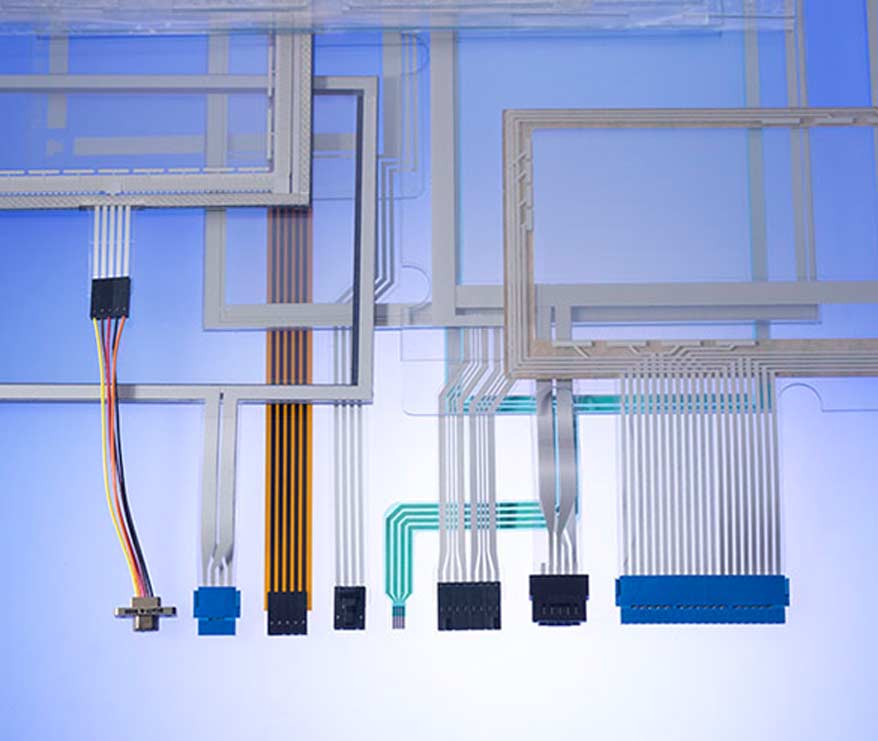

Tails

Touchscreen tails fall into two major categories, integrated tail(s) and bonded tail(s). As the name implies an integrated tail is an extension of either one (for two layer construction) or both (for three layer construction) touchscreen layers. A bonded tail is typically a flexible tail that is bonded to the substrate via ACF (Anisotropic Conductive Film) or ACP (Anisotropic Conductive Paste). These are typically made of copper on Kapton or PET, or silver epoxy on PET. Both types can be designed to accept crimped on connectors or they can be used with FPC (Flexible Printed Circuit) or FFC (Flat Flexible Cables) type connectors.

Integrated tails provide better pull strength, are more reliable, and are cost effective, provided that the tail is not too long and is positioned properly.

Bonded tails are extremely flexible, and in some cases can even be creased, to accommodate tight spaces. And, due to the durability of the copper conductors, they are a better choice to mate with ZIF (zero insertion force) and especially non-ZIF FPC connectors. These tails are also a better choice when the spacing of the conductors is less than 1mm.