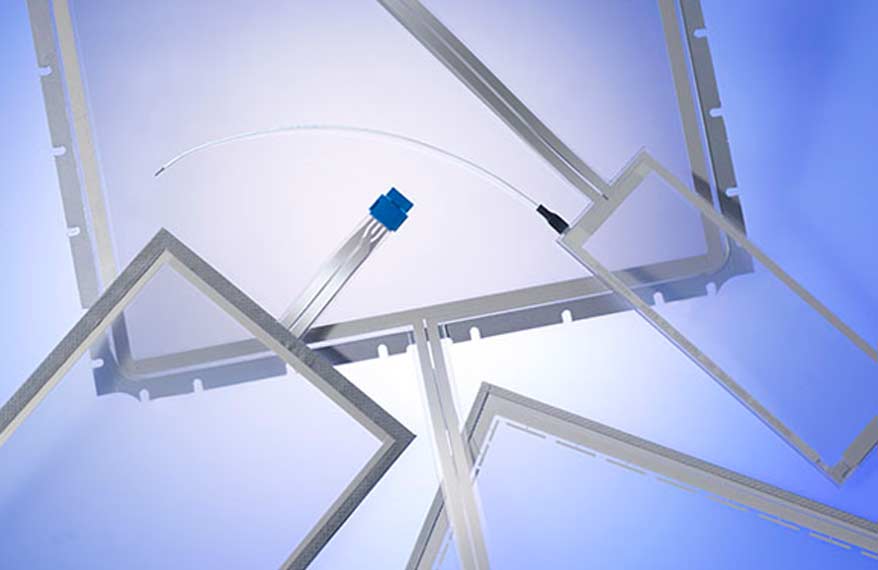

Shields and Protection

A transparent and conductive shield layer or layers may be added to a touchscreen to protect against EMI and ESD. These layers are typically conductive films optically laminated on the front or the back side of a touchscreen. It is also possible to deposit a low resistance conductive coating directly on the back side of a touchscreen’s substrate. Shielding gaskets, or other means, such as conductive tapes or grounding straps are then used to ground these layers to a chassis ground. The shield layer absorbs the EMI and redirects any ESD discharge to the ground and therefore protects the electronics against these phenomena.

Some of the shielding techniques include the use of blackened wire mesh imbedded in glass or plastic layers, low resistance conductive coatings on PET and other plastics, and low resistance conductive coatings on glass. TPI’s shielding techniques, developed over years of manufacturing parts for military and medical applications, will ensure the safety of your electronics as well as the users interacting with your products. Shielding efficiencies, achieved by these techniques, satisfy the stringent military shielding requirements.

Choosing the right shielding

Careful and knowledgeable selection of these shields will guarantee both shielding effectiveness and will ensure minimal impact on optical and mechanical performance of the touchscreen.

Please contact one of our application engineers at 661-294-9787 to review your specific requirements and to help you select the best combination of shielding performance and mechanical and optical compatibility.